We provide outstanding customer value to a worldwide clientele for applications in industrial, rolling stock, marine, offshore, renewable energy and power generation markets.

Our products meet the highest technical standards in order to satisfy the most exigent client specifications.

All the manufacturing processes are driven by respect for the environment.

Our company culture is based on continuous improvement of technology and processes to offer exceptional and cost efficient products and services.

Our most valuable resource is the human capital formed by the staff at all levels.

We organize work in such way to ensure the greatest personal satisfaction for everyone as well as to create good chances of professional advancement for those that perform well.

We conduct all business in fairness and mindful of the rights and expectations of our clients, employees, suppliers, shareholders and other stakeholders.

Sebastiano Zumbino, CEO

Cristian Cipolletta, Operation Manager

Giovanni Narcisi, Sales Director

This is one of the main activities of Trasfor into which we channel significant investments in both simulation systems and experiments in our laboratories. Collaboration with institutes, specialized centers and universities promote the multidisciplinary nature of research and development. The Swiss Confederation provides concrete backing for the developments promoted by our company.

Our activities are divided between the pursuit of technical development for our clients and the development of our own projects. The first one is a research activity with the characteristics of consultation and integration with the customer, and usually includes lead times, while the second one is driven by corporate strategies, both in terms of basic research and applied research for a specific product.

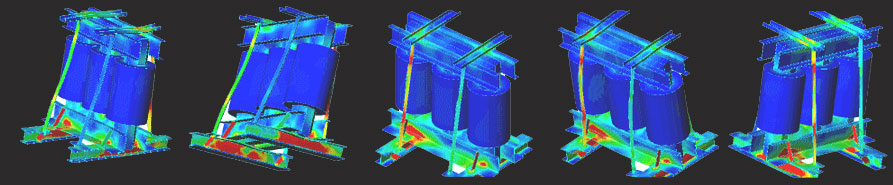

The research environment makes use of advanced development tools, both mechanical: Pro/Mechanica-De-featuring Pre-processing, preliminary analyzes (Static, Dynamic, Shock), simple post-processing; MSC Patran-Pre processing , detailed post-processing; MSC Nastranaccurate analyzes (Static, Dynamic, Shock, Fatigue) MSC Fatigue-Fatigue analysis and electrical: Comsol Multiphysics and its modules: AC/DC Module- Conductive Media DC; Shell Conductive Media Dc; Electrostatics; 3D Quasi-Statics, Electromagnetic; 3D Quasi-Statics, Magnetic; 3D Quasi-Statics, Electric; 2D Perpendicular and Azimuthal Induction Currents, Vector Potential. In addition to the Heat Transfer Module and its components; General Heat Transfer (2D and 3D) Stationary and Time-dependent; Thin Conductive Shell Stationary and Time-dep; Weakly Compressible Navier-Stokes (2D and 3D) Stationary and Time-dependent.